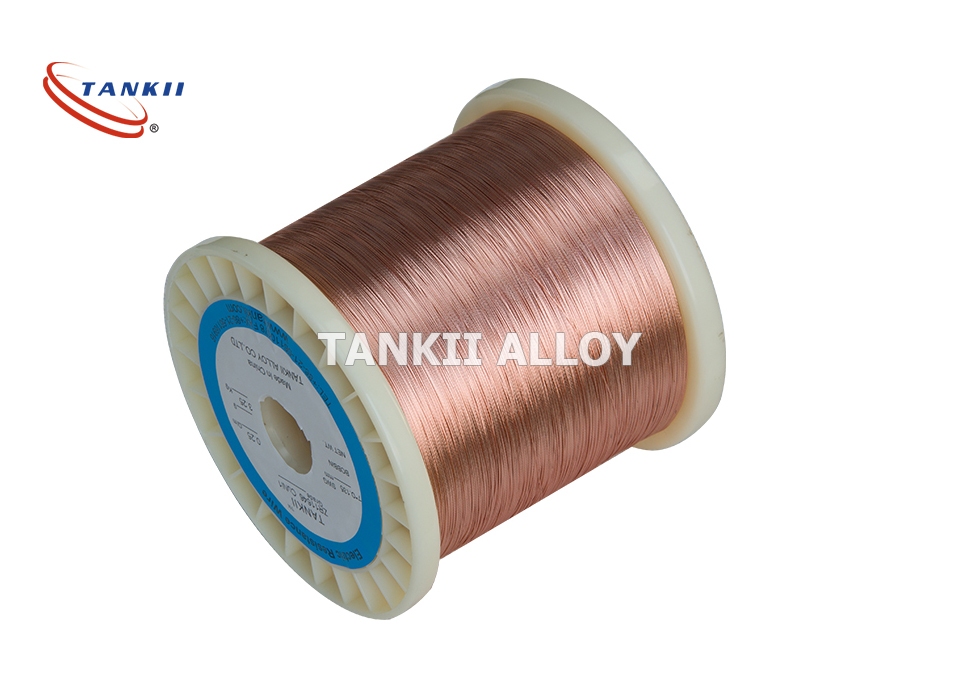

Uea Palekana Nickel CuNi i hoʻopaʻa ʻia me ka hao hao 180 Manganin

Nicr ma muli o ke keleawe poepoeAlloy 180uea keleawe enamel insulated papa kekelē

1. Ka Wehewehe Laulā o nā Mea Hana

1)

ManganīnaHe mea hoʻohuihui ia o 84% keleawe, 12% manganese, a me 4% nickel.

Hoʻohana ʻia ka uea Manganin a me ka foil i ka hana ʻana i nā resistors, ʻoiai ka ammeter shunt, ma muli o kona coefficient mahana ʻole o ke kū'ē a me ke kūpaʻa lōʻihi. Ua lawelawe kekahi mau resistors Manganin ma ke ʻano he kūlana kānāwai no ka ohm ma ʻAmelika Hui Pū ʻIa mai 1901 a 1990. Hoʻohana ʻia ka uea Manganin ma ke ʻano he alakaʻi uila i nā ʻōnaehana cryogenic, e hoʻemi ana i ka hoʻoili wela ma waena o nā wahi e pono ai nā pilina uila.

Hoʻohana ʻia ʻo Manganin i nā ana no nā haʻawina o nā nalu haʻalulu kiʻekiʻe (e like me nā mea i hana ʻia mai ka pahū ʻana o nā mea pahū) no ka mea he haʻahaʻa kona ʻike koʻikoʻi akā he kiʻekiʻe kona ʻike kaomi hydrostatic.

2)

ʻO Constantanhe mea hoʻohuihui keleawe-nickel i ʻike ʻia hoʻiʻEureka, Hoʻomaka, a meWaʻa Hoʻokele. ʻO ka maʻamau, he 55% keleawe a me 45% nickel. ʻO kona hiʻohiʻona nui kona resistivity, kahi e mau ana ma luna o nā ʻano mahana like ʻole. Ua ʻike ʻia nā mea hoʻohui ʻē aʻe me nā coefficients mahana haʻahaʻa like, e like me ka manganin (Cu86Mn12Ni2).

No ke ana ʻana o nā ʻano nui loa, 5% (50 000 microstrian) a i ʻole ma luna, ʻo ka constantan annealed (P alloy) ka mea grid i koho maʻamau ʻia. He ductile loa ʻo Constantan ma kēia ʻano; a, i nā lōʻihi gauge o 0.125 ʻīniha (3.2 mm) a ʻoi aku ka lōʻihi, hiki ke kānana ʻia i >20%. Eia naʻe, pono e hoʻomanaʻo ʻia, ma lalo o nā ʻano cyclic kiʻekiʻe, e hōʻike ka P alloy i kekahi loli resistivity mau loa me kēlā me kēia pōʻaiapuni, a hana i kahi neʻe like ʻole i ka strain gauge. Ma muli o kēia ʻano, a me ke ʻano no ka hāʻule mua ʻana o ka grid me ka kānana hou ʻana, ʻaʻole i ʻōlelo pinepine ʻia ka P alloy no nā noi strain cyclic. Loaʻa ka P alloy me nā helu STC o 08 a me 40 no ka hoʻohana ʻana ma nā metala a me nā plastics.

2. Hoʻolauna ʻana i ka Uea Enamelled a me nā noi

ʻOiai ua wehewehe ʻia he "enameled", ʻaʻole i uhi ʻia ka uea enameled me kahi papa o ka pena enamel a ʻaʻole hoʻi me ka enamel vitreous i hana ʻia me ka pauka aniani i hoʻohui ʻia. Hoʻohana pinepine ka uea magnet hou i hoʻokahi a ʻehā mau papa (i ke ʻano o ka uea ʻano quad-film) o ka insulation film polymer, pinepine o ʻelua mau ʻano like ʻole, e hāʻawi i kahi papa insulation paʻa a hoʻomau. Hoʻohana nā kiʻiʻoniʻoni insulating wire magnet (ma ke ʻano o ka piʻi ʻana o ka pae mahana) polyvinyl formal (Formar), polyurethane, polyimide, polyamide, polyster, polyester-polyimide, polyamide-polyimide (a i ʻole amide-imide), a me polyimide. Hiki i ka uea magnet insulated Polyimide ke hana a hiki i 250 °C. Hoʻonui pinepine ʻia ka insulation o ka uea magnet square a rectangular mānoanoa ma ke kāʻei ʻana me kahi polyimide wela kiʻekiʻe a i ʻole ka lipine fiberglass, a ʻo nā wili i hoʻopau ʻia e hoʻomaʻemaʻe pinepine ʻia me kahi varnish insulating e hoʻomaikaʻi i ka ikaika insulation a me ka hilinaʻi lōʻihi o ka wili.

Ua ʻōwili ʻia nā wili kākoʻo ponoʻī me ka uea i uhi ʻia me ka liʻiliʻi o ʻelua papa, ʻo ka mea waho loa he thermoplastic e hoʻopaʻa ana i nā wili i ka wā e hoʻomehana ʻia ai.

ʻO nā ʻano insulation ʻē aʻe e like me ke olonā fiberglass me ka varnish, ka pepa aramid, ka pepa kraft, ka mica, a me ka polyester film e hoʻohana nui ʻia ma ka honua holoʻokoʻa no nā noi like ʻole e like me nā transformers a me nā reactors. Ma ka ʻāpana leo, hiki ke loaʻa kahi uea o ke kūkulu kālā, a me nā insulators ʻē aʻe, e like me ka pulupulu (i kekahi manawa i hoʻopiha ʻia me kekahi ʻano coagulating agent/thickener, e like me ka beeswax) a me ka polytetrafluoroethylene (PTFE). ʻO nā mea insulation kahiko e komo pū ana me ka pulupulu, ka pepa, a i ʻole ka silika, akā he mea pono wale nō kēia no nā noi haʻahaʻa haʻahaʻa (a hiki i 105°C).

No ka maʻalahi o ka hana ʻana, aia kekahi uea magnet haʻahaʻa haʻahaʻa i loaʻa ka insulation hiki ke wehe ʻia e ka wela o ke kūʻai ʻana. ʻO ke ʻano kēia, hiki ke hana ʻia nā pilina uila ma nā wēlau me ka ʻole o ka wehe ʻana i ka insulation ma mua.

3. ʻO ka hoʻohuihui kemika a me ka waiwai nui o Cu-Ni Low Resistance Alloy

| Nā WaiwaiPae | CuNi1 | CuNi2 | CuNi6 | CuNi8 | CuMn3 | CuNi10 | |

| ʻO ka Hoʻohui Kemika Nui | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | Bal | Bal | Bal | Bal | Bal | Bal | |

| Ka Mahana Hana Hoʻomau Loa (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Ke kūpaʻa ʻana ma 20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Ka nui (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Ka Hoʻokele Wela (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Ikaika Tensile (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Wahi Hoʻoheheʻe Kokoke (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| ʻAno Micrographic | ʻaustenite | ʻaustenite | ʻaustenite | ʻaustenite | ʻaustenite | ʻaustenite | |

| Waiwai Makeneka | ʻaʻole | ʻaʻole | ʻaʻole | ʻaʻole | ʻaʻole | ʻaʻole | |

| Nā WaiwaiPae | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNi44 | |

| ʻO ka Hoʻohui Kemika Nui | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | Bal | Bal | Bal | Bal | Bal | Bal | |

| Ka Mahana Hana Hoʻomau Loa (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Ke kūpaʻa ʻana ma 20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Ka nui (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Ka Hoʻokele Wela (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Ikaika Tensile (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Wahi Hoʻoheheʻe Kokoke (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| ʻAno Micrographic | ʻaustenite | ʻaustenite | ʻaustenite | ʻaustenite | ʻaustenite | ʻaustenite | |

| Waiwai Makeneka | ʻaʻole | ʻaʻole | ʻaʻole | ʻaʻole | ʻaʻole | ʻaʻole | |

Nā māhele huahana

-

Kelepona

-

Leka uila

-

Whatsapp

-

WeChat

ʻO Judy

150 0000 2421

-

Luna