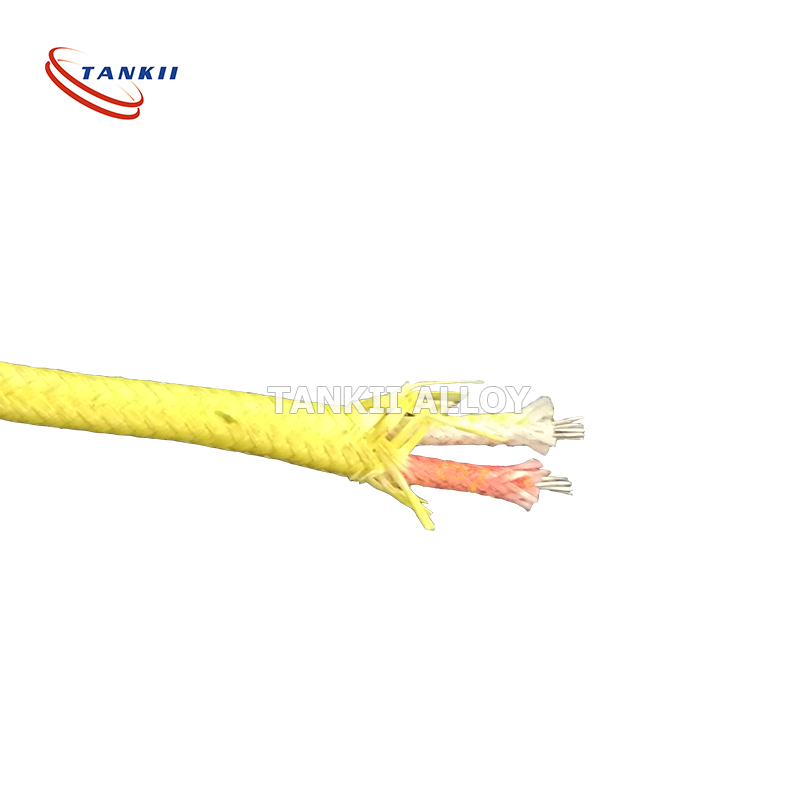

Papa F nylon/ho'ololi polyester enameled poepoe keleawe uea

Papa Fnilona/ hoʻololi polyester enamled poepoeuwea keleawe

Hōʻike huahana

Ua hoʻohana nui ʻia kēia mau uea kūʻē enamel no nā resistors maʻamau, kaʻa

nā ʻāpana, nā mea pale wili, a me nā mea ʻē aʻe e hoʻohana ana i kahoʻokaʻawaleʻoi aku ka maikaʻi o ka hana ʻana no kēia mau noi, me ka hoʻohana piha ʻana i nā hiʻohiʻona kūʻokoʻa o ka uhi enamel.

Eia kekahi, e hana mākou i ka uhi enamelhoʻokaʻawaleo ka uwea metala makamae e like me ke kala a me ka uea platinum ma ke kauoha. E ʻoluʻolu e hoʻohana i kēia production-on-order.

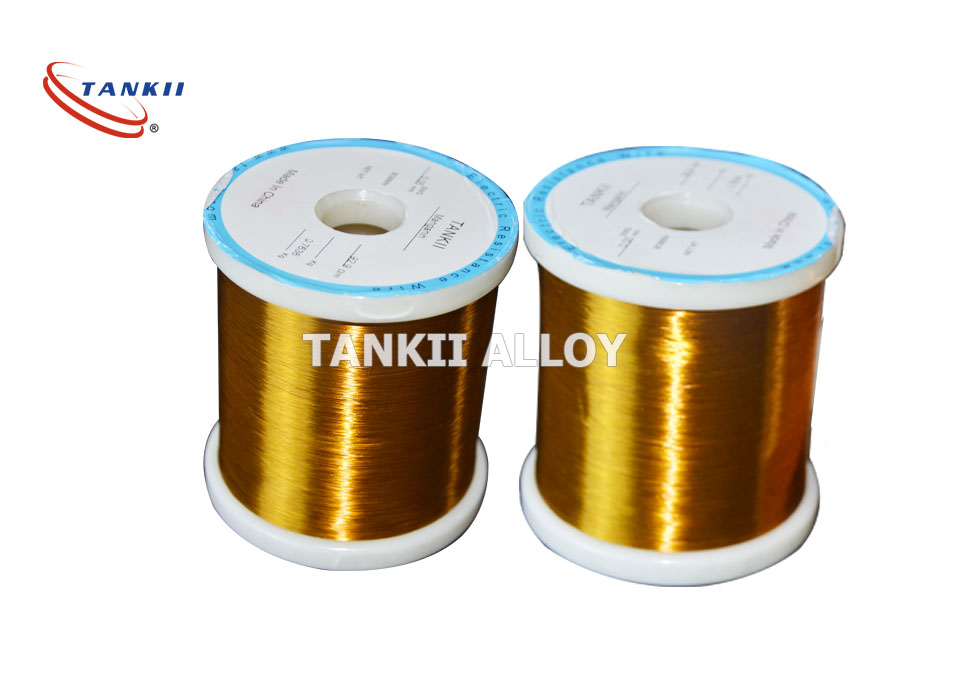

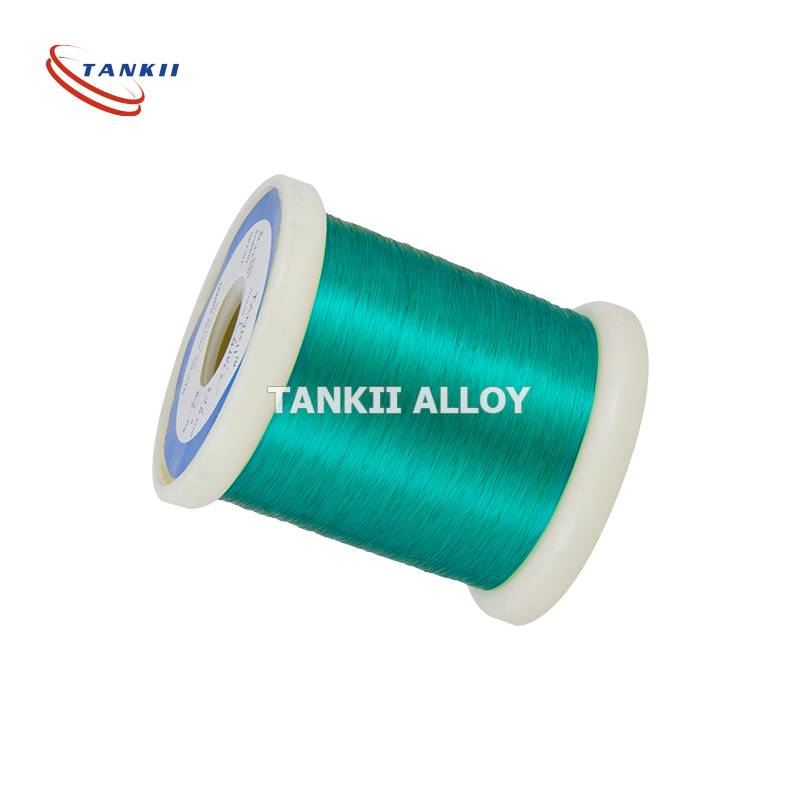

Ke ʻano o ka uea Alloy ʻole

ʻO ka alloy hiki iā mākou ke hana i enamelled he uea copper-nickel alloy, uea mau, uea manganin. Kama Wire, NiCr Alloy wire, FeCrAl Alloy wire etc

Ke ʻano o ka hoʻopulapula

| Insulation-enamelled inoa | Papa welaºC (manawa hana 2000h) | Helu inoa | GB Code | ANSI. ANO |

| uwea polyurethane enamelled | 130 | UEW | QA | MW75C |

| uwea poliester enamelled | 155 | PEW | QZ | MW5C |

| uwea poliester-imide enamelled | 180 | EIW | QZY | MW30C |

| ʻO ka polyester-imide a me ka polyamide-imide lua i uhi ʻia i ka uwea enamel | 200 | EIWH (DFWF) | QZY/XY | MW35C |

| ʻO ka uwea polyamide-imide enamelled | 220 | AIW | QXY | MW81C |

Maʻiʻo Kemika, %

| Cu | Bi | Sb | As | Fe | Ni | Pb | S | Zn | Kuhikuhi ROHS | |||

| Cd | Pb | Hg | Cr | |||||||||

| 99.90 | 0.001 | 0.002 | 0.002 | 0.005 | - | 0.005 | 0.005 | - | ND | ND | ND | ND |

Na Waiwai Kino

| Lae hehee – Liquidus | 1083ºC |

| Lae hehee – Solidus | 1065ºC |

| ʻO ka mānoanoa | 8.91 gm/cm3@ 20 ºC |

| Kaumaha Kūikawā | 8.91 |

| Kū'ē Uila | 1.71 microhm-cm @ 20 ºC |

| Ka hoʻoheheʻe uila** | 0.591 MegaSiemens/cm @ 20 ºC |

| ʻO ka hoʻoili wela | 391.1 W/m ·oK ma 20 C |

| Coefficient o ka hoonui wela | 16.9 ·10-6perºC(20-100 ºC) |

| Coefficient o ka hoonui wela | 17.3 ·10-6perºC(20-200 ºC) |

| Coefficient o ka hoonui wela | 17.6·10-6perºC(20-300 ºC) |

| Kaha Wela Kūikawā | 393.5 J/kg ·oK ma 293 K |

| Modulus o ka Elasticity i ka Tension | 117000 Mpa |

| Modulus o Rigidity | 44130 Mpa |

Ka hoʻohana ʻana o Copper foil

1) Uila a me nā punawai uila, nā kī

2) Nā papa alakaʻi

3) Nā mea hoʻohui a me nā ʻohe oscillation

3) PCB kahua

4) Uea kamaʻilio, Kaʻa kaua, Mobile Phone mainboard

5) ʻO ka lamination pākaukau Ion me ka kiʻiʻoniʻoni PI

6) ʻOhi PCB (hoʻihoʻi electrode) mau mea

Māhele huahana

-

Kelepona

-

leka uila

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

luna