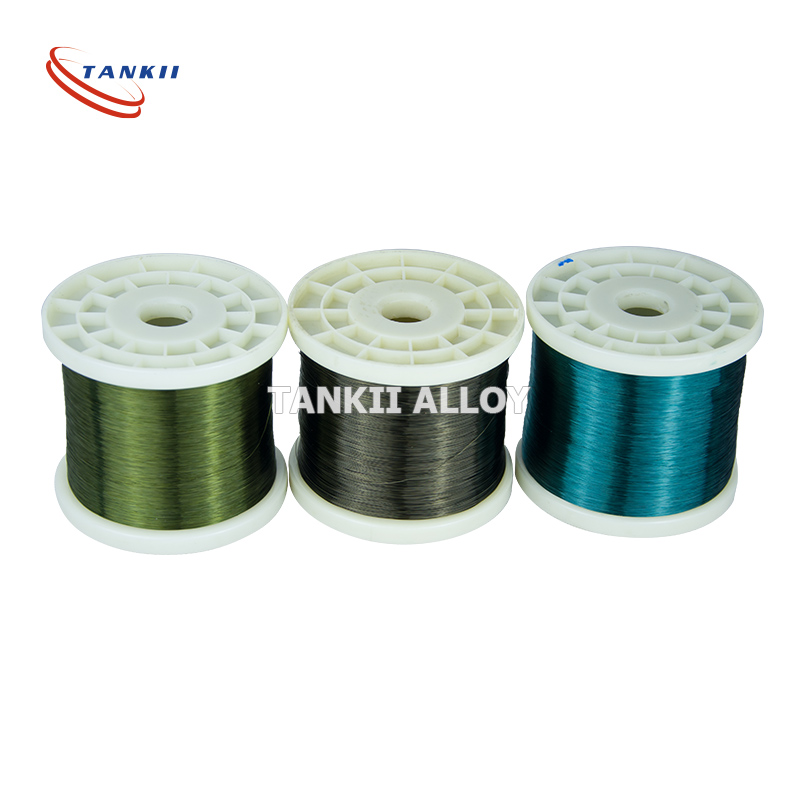

uea keleawe wela papa C / 200 * C ANSI TYPE MW35C a i ʻole IEC 317-13. Uea wili enameled i uhi pālua ʻia me ka polyester-imide a me ka polyamide-imide

uea keleawe papa wela C/ 200*C ANSI TYPE MW35C a i ʻole IEC 317-13. ʻO Polyester-imide a mepolyamide-imideuea wili ʻenamelo pālua

Wehewehe Huahana

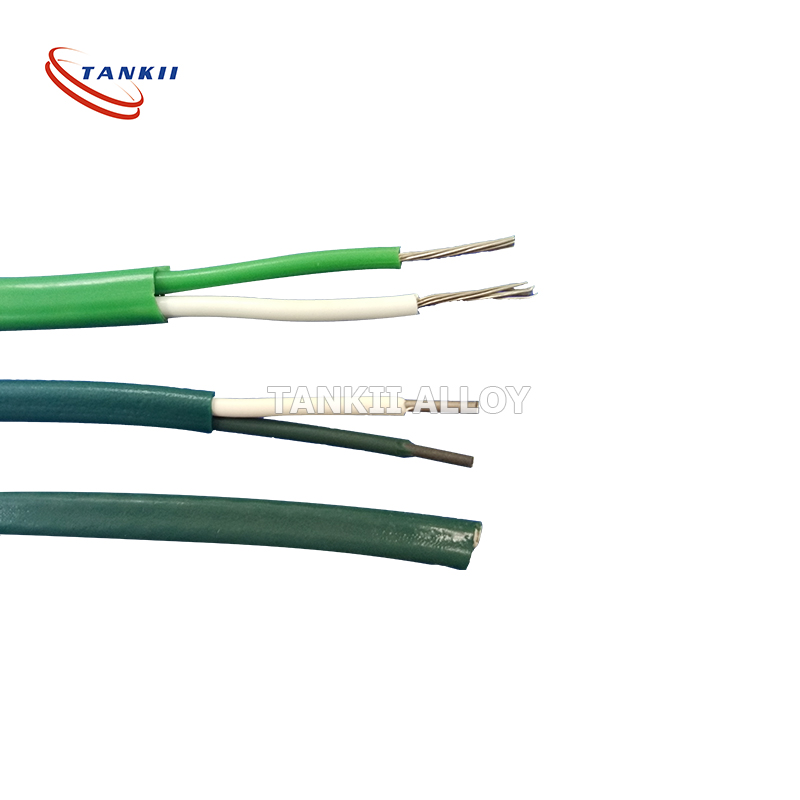

Ua hoʻohana nui ʻia kēia mau uea kū'ē enameled no nā resistors maʻamau, nā kaʻa

nā ʻāpana, nā pale wili, a pēlā aku. me ka hoʻohana ʻana i kaka pale ʻanaka hana ʻana i kūpono loa no ia mau noi, e hoʻohana pono ana i nā hiʻohiʻona kūikawā o ka uhi enamel.

Eia kekahi, e hana mākou i ka uhi ʻana i ka enamelka pale ʻanao ka uea metala makamae e like me ke kālā a me ka uea platinum ma ke kauoha. E ʻoluʻolu e hoʻohana i kēia hana-ma-ke kauoha.

ʻAno o ka Uea Nichrome

NiCr80/20,NiCr70/30,NiCr60/15,NiCr90/10,NiCr35/20,NiCr30/20

ʻAno o ka pale ʻana

| Inoa enamel-insulation | Pae WeraºC (manawa hana 2000h) | Inoa Kōmike | Kōmike GB | ʻAno ANSI |

| Uea enamelled polyurethane | 130 | ʻUEW | QA | MW75C |

| Uea enamelled polyester | 155 | PEW | QZ | MW5C |

| Uea enamelled polyester-imide | 180 | EIW | QZY | MW30C |

| Uea enameled i uhi ʻia me ka polyester-imide a me ka polyamide-imide | 200 | ʻEIWH (DFWF) | QZY/XY | MW35C |

| Uea enamelled polyamide-imide | 220 | AIW | QXY | MW81C |

ʻAno o ka Uea Alloy ʻōlohelohe

ʻO ka mea hoʻohuihui hiki iā mākou ke hana i ka enamelled he uea keleawe-nickel, uea Constantan, uea Manganin. Kama Wire, uea NiCr Alloy, uea FeCrAl Alloy etc.

| mea nui waiwai ʻano | ʻO Cuni1 | ʻO CuNI2 | CuNI6 | CuNi8 | CuNI10 | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNI44 | ||

| mea nui kemika haku mele | Ni | 1 | 2 | 6 | 8 | 10 | 14.2 | 19 | 23 | 30 | 34 | 44 | |

| MN | / | / | / | / | / | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | ||

| CU | hoʻomaha | hoʻomaha | hoʻomaha | hoʻomaha | hoʻomaha | hoʻomaha | hoʻomaha | hoʻomaha | hoʻomaha | hoʻomaha | hoʻomaha | ||

| ka nui loa e hana ana mahana | / | 200 | 220 | 250 | 250 | 300 | 300 | 300 | 350 | 350 | 400 | ||

| ka nui o ka paʻa g/cm3 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | ||

| ke kū'ē ʻana ma 20°c | 0.03 ± 10% | 0.05± 10% | 0.10± 10% | 0.12± 10% | 0.15± 10% | 0.20± 5% | 0.25± 5% | 0.30± 5% | 0.35± 5% | 0.40± 5% | 0.49± 5% | ||

| mahana koina o ke kū'ē | <100 | <120 | <60 | <57 | <50 | <38 | <25 | <16 | <10 | -0 | <-6 | ||

| ʻūmiʻi ikaika mpa | >210 | >220 | >250 | >270 | >290 | >310 | >340 | >350 | >400 | >400 | >420 | ||

| hoʻolōʻihi | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | ||

| hoʻoheheʻe ʻana kiko °c | 1085 | 1090 | 1095 | 1097 | 1100 | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | ||

| koina o alakaʻi uila | 145 | 130 | 92 | 75 | 59 | 48 | 38 | 33 | 27 | 25 | 23 |

uea hoʻomehana nicr8020

1.E pili ana i ka uea Nichrome

ʻO ke kinikini Nichrome e komo pū ana me ka nickel maʻemaʻe, ka kinikini NiCr, ka kinikini Fe-Cr-Al a me ke kinikini keleawe.

Nā mea hoʻohui nikala chrome: Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni30Cr20, Cr25Ni20, nikala maʻemaʻe Ni200 a me Ni201

2. Ka Pōmaikaʻi Nui a me ka Noi ʻana

1. Nickel-chromium, he hui nickel-chromium me ke kūpaʻa kiʻekiʻe a paʻa, kūpaʻa i ka pala, maikaʻi ke kūpaʻa ʻana i ka ʻokikene ʻili, ʻoi aku ka maikaʻi ma mua o ke kiʻekiʻe o ka mahana a me ka ikaika seismic, ductility maikaʻi, hana maikaʻi a me ka weldability.

2. Hoʻopili nui kā mākou huahana i ka ʻoihana kemika, ka mīkini metallurgy, ka ʻoihana aniani, ka ʻoihana seramika, ka ʻāpana lako home a pēlā aku.

3. Ke ʻano kemika:

| Lama | ʻAno kemika | Si | Cr | Ni | Al | Fe | |||

| C | P | S | Mn | ||||||

| ʻAʻole ʻoi aku ma mua o | |||||||||

| Cr20Ni80 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 20.0-23.0 | noho | ≤0.50 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 15.0-18.0 | 55.0-61.0 | ≤0.50 | noho |

| Cr20Ni35 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-3.00 | 18.0-21.0 | 34.0-37.0 | - | noho |

| Cr20Ni30 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-2.00 | 18.0-21.0 | 30.0-34.0 | - | noho |

Ke kūlana "M" ka huahana, pono e hahai ʻia ke kūlana GB/T1234-1995

Ke kū'ē ʻana:

| Lama | Cr20Ni80 | Cr20Ni60 | Cr20Ni35 | Cr20Ni30 | ||

| Anawaena mm | <0.50 | 0.50-3.0 | <0.50 | ≥0.50 | <0.50 | ≥0.50 |

| ke kū'ē (20°C)uΩ·m | 1.09±0.05 | 1.13±0.05 | 1.12±0.05 | 1.15±0.05 | 1.04±0.05 | 1.06±0.05 |

Nā māhele huahana

-

Kelepona

-

Leka uila

-

Whatsapp

-

WeChat

ʻO Judy

150 0000 2421

-

Luna