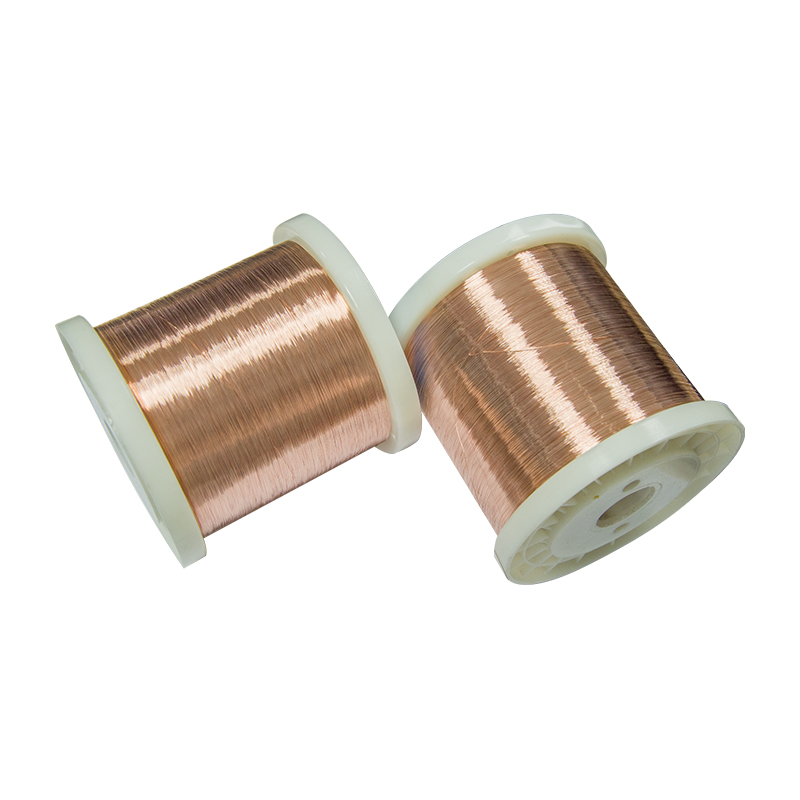

CuNi40(6J40) Alloy Copper Nickel Constantan Wire

Hoʻohana nui ʻia ka mea keleawe haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa i ka haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa, thermal overload relay, a me nā huahana uila haʻahaʻa haʻahaʻa. ʻO ia kekahi o nā mea nui o nā huahana uila haʻahaʻa haʻahaʻa. ʻO nā mea i hanaʻia e kā mākou hui he mau hiʻohiʻona o ke kūpaʻa kūpaʻa maikaʻi a me ke kūpaʻa kiʻekiʻe. Hiki iā mākou ke hoʻolako i nā ʻano uea poepoe a pau, nā mea palahalaha a me ka pepa.

CuNi40(6J40)

ConstantanaʻO CuNi40, i kapa ʻia ʻo 6J40, he mea hoʻokūkū kūʻē i hana nui ʻia me ke keleawe a me ka nickel.

Loaʻa iā ia ke koena haʻahaʻa haʻahaʻa haʻahaʻa, ākea ka wela wela o ka hana (500 ma lalo), maikaʻi machiningproperty, anti-corrosive a me ka maʻalahi braze welding.

ʻAʻole magnetik ka alloy. Hoʻohana ʻia ia no ka resistor hoʻololi o ka uila regenerator a me ka resistor strain,

potentiometers, uwea wela, uwea wela a me ka moena. Hoʻohana ʻia nā lipine no ka hoʻomehana ʻana i nā bimetal. ʻO kahi ʻano noiʻi ʻē aʻe ʻo ka hana ʻana i nā thermocouple no ka mea e hoʻomohala ana i ka ikaika electromotive kiʻekiʻe (EMF) i hui pū me nā metala ʻē aʻe.

Copper nickel alloy series:ConstantanaCuNi40 (6J40), CuNi1, CuNi2, CuNi6, CuNi8, CuNi10, CuNi14, CuNi19, CuNi23, CuNi30, CuNi34, CuNi44.

Nā māka nui a me nā waiwai

| ʻAno | ʻAiʻa uila (20 degereΩ mm²/m) | koena wela o ke kū'ē (10^6/degere) | Dens keia g/mm² | Max. mahana wela (°c) | Lae hehee (°c) |

| CuNi1 | 0.03 | <1000 | 8.9 | / | 1085 |

| CuNi2 | 0.05 | <1200 | 8.9 | 200 | 1090 |

| CuNi6 | 0.10 | <600 | 8.9 | 220 | 1095 |

| CuNi8 | 0.12 | <570 | 8.9 | 250 | 1097 |

| CuNi10 | 0.15 | <500 | 8.9 | 250 | 1100 |

| CuNi14 | 0.20 | <380 | 8.9 | 300 | 1115 |

| CuNi19 | 0.25 | <250 | 8.9 | 300 | 1135 |

| CuNi23 | 0.30 | <160 | 8.9 | 300 | 1150 |

| CuNi30 | 0.35 | <100 | 8.9 | 350 | 1170 |

| CuNi34 | 0.40 | -0 | 8.9 | 350 | 1180 |

| CuNi40 | 0.48 | ±40 | 8.9 | 400 | 1280 |

| CuNi44 | 0.49 | <-6 | 8.9 | 400 | 1280 |

Māhele huahana

-

Kelepona

-

leka uila

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

luna