Welina mai i kā mākou mau pūnaewele!

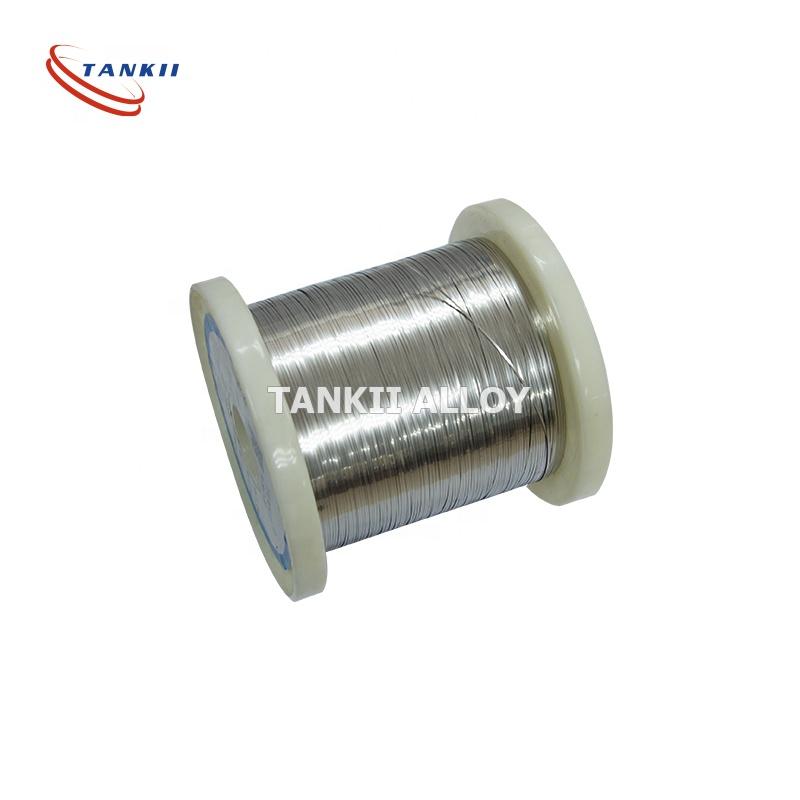

ʻO ka uea pālahalaha a me ke kaha hoʻomehana FeCrAl 0cr23al5 e ka hale hana

ʻO ka uea pālahalaha o ka mea hoʻomehana FeCrAl 0cr23al5 &ʻāpanae ka hale hana

| Papa | 0Cr23Al5 |

| Ka nui | mānoanoa: 0.05-3mm laulā: 4-250mm |

| ʻIli | ʻoki ʻālohilohi |

| Kaumaha | 1-3kg/'ōwili, e like me ka nui o nā mea kūʻai aku |

| Ke kū'ē ʻana | 1.3±0.05μΩ.m |

| Paʻakikī (HV) | 180-210HV |

| Hoʻolōʻihi | ≥16% |

| Papa | Mahana kiʻekiʻe loa | Ke kū'ē ʻana | Paʻakikī | Ikaika tensile | Hoʻolōʻihi |

| 0Cr13Al4 | 1050℃ | 1.25±0.05μΩ.m | 180-210HV | ≥550N/mm2 | ≥16 |

| 0Cr15Al5 | 1100℃ | 1.3±0.05μΩ.m | 180-210HV | ≥550N/mm2 | ≥16 |

| 0Cr21Al6Nb | 1300℃ | 1.42±0.05μΩ.m | 200-240HV | 750N/mm2 | ≥12 |

| Cr20Ni80 | 1200℃ | 1.09±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Cr15Ni60 | 1150℃ | 1.12±0.05μΩ.m | 175-210HV | 750N/mm2 | ≥20 |

| Cr20Ni35 | 1100℃ | 1.04±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Cr25Ni20(310S) | 1100℃ | 0.86±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Papa | Ka hoʻohuihui kemika% | ||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | |

| ≤ | |||||||||

| 0Cr15Al5 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | <1 | 4.8-5.0 | kaulike |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.02 | 0.5 | ≤0.6 | 21-23 | ≤0.6 | 5-7 | kaulike |

| 0Cr13Al4 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | <1 | 4.8-5.0 | kaulike |

| Cr20Ni80 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 20-23 | kaulike | <0.5 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 15-18 | 55-61 | <0.5 | kaulike |

| Cr20Ni35 | 0.08 | 0.02 | 0.015 | 1.0 | 1-3 | 18-21 | 34-37 | - | kaulike |

| Cr25Ni20 | 0.08 | 0.045 | 0.03 | 2.0 | 0.4-0.6 | 24-26 | 19-22 | - | kaulike |

Ke nānā aku nei ʻo Shanghai Tankii ALloy Material Co., Ltd. i ka hana ʻana o ka nichrome alloy, thermocouple wire, fecral alloy, precision alloy, copper nickel alloy, thermal spray alloy etc. ma ke ʻano o ka uea, pepa, lipine,ʻāpana,koʻokoʻo a me ka pā.

Ua loaʻa iā mākou ka palapala hōʻoia ʻōnaehana maikaʻi ISO 9001 a me ka ʻae ʻia o ka ʻōnaehana palekana kaiapuni ISO 14001. Loaʻa iā mākou kahi hoʻonohonoho piha o ke kahe hana holomua o ka hoʻomaʻemaʻe ʻana, ka hoʻemi anu, ke kaha kiʻi a me ka mālama wela a pēlā aku. Loaʻa iā mākou ka mana R&D kūʻokoʻa.

E kākau i kāu leka ma aneʻi a hoʻouna mai iā mākou

Nā māhele huahana

-

Kelepona

-

Leka uila

-

Whatsapp

-

WeChat

ʻO Judy

150 0000 2421

-

Luna