Welina mai i kā mākou mau pūnaewele!

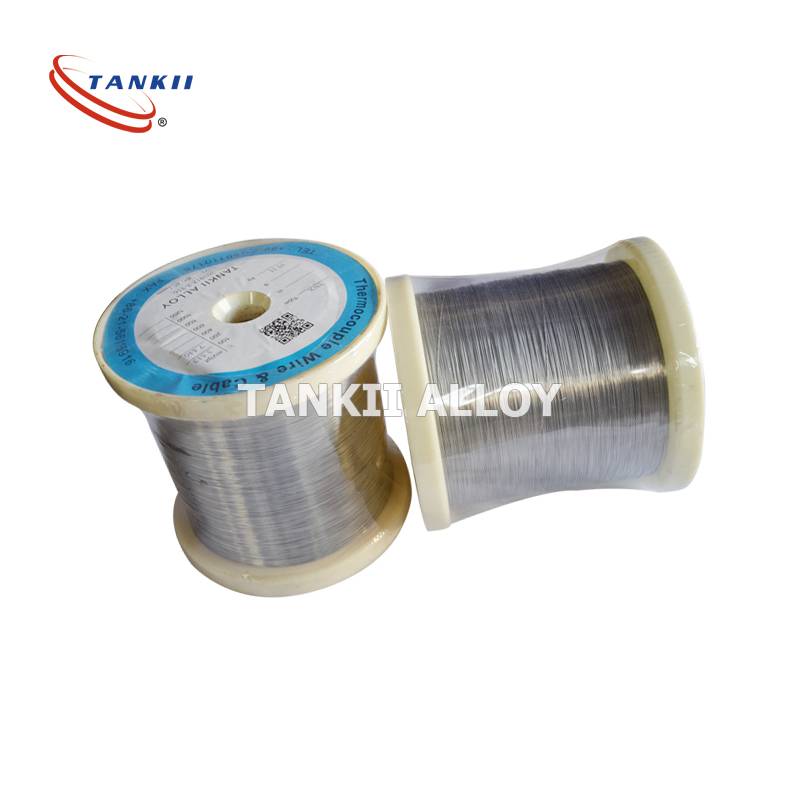

Uea uila pale wela FeCrAl FeCr23Al5 A1 APM AF D Alloy

Uea uila kūpaʻa wela FeCrAl A1 APM AF D Alloy

E pili ana i ka uea hoʻomehana kū'ē:

ʻO mākou ka mea hana ʻoihana nui loa o ka mea hoʻomehana pale kū'ē ma Kina, kūikawā i ka uea Ferro-Chrome (Fe-Cr-AL), uea Nickel-Chrome (Nichrome), uea Copper Nickel (Constantan), uea kila kila a me nā huahana pili i nā mea hoʻohui i hana ʻia e hoʻokō i nā koi kikoʻī o ka mea kūʻai aku.

Nā kikoʻī nui

| Inoa huahana | Pae nui |

| Uea kaha anu | Anawaena 0.03-7.5mm |

| ʻO ke koʻokoʻo uea i ʻōwili wela ʻia | Anawaena 8.0-12mm |

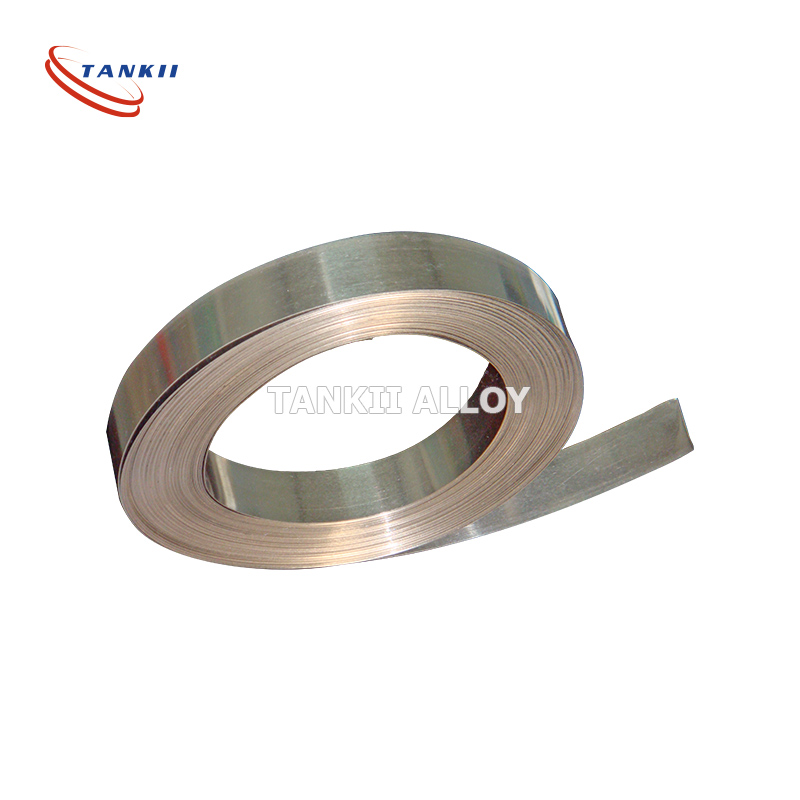

| Lipine | Mānoanoa 0.05-0.35mm |

| Ka laulā 0.5.0-3.5mm | |

| ʻO ka ʻōwili anu | Mānoanoa 0.5-2.5mm |

| Ka laulā 5.0-40mm | |

| ʻōwili wela | Mānoanoa 4-6mm |

| Ka laulā 15-40mm |

nā palena kumu:

| nā palena kumu | APMTM | ʻO FeCrAl | ||

| A-1 | AF | D | ||

| ʻO ka mahana hana mau loa kiʻekiʻe loa | 1425 | 1400 | 1300 | 1300 |

| ʻO ka hoʻohuihui kemika maʻamau,% Cr | 22 | 22 | 22 | 22 |

| AI | 5.8 | 5.8 | 5.3 | 4.8 |

| Fe | nā mea hoʻohui | nā mea hoʻohui | nā mea hoʻohui | nā mea hoʻohui |

| Ni | - | - | - | - |

| ʻO ke kū'ē'ē ma 20ºC,Ωmm-2mm-1 | 1.45 | 1.45 | 1.39 | 1.35 |

| ka nui o ka paʻa, g/cm3 | 7.1 | 7.1 | 7.15 | 7.25 |

| Ka helu hoʻonui wela K-1 20-750ºC | 14×10-6 | 14×10-6 | 14×10-6 | 14×10-6 |

| 20-1000ºC | 15×10-6 | 15×10-6 | 15×10-6 | 15×10-6 |

| ʻO ke alakaʻi wela 20ºC, Wm-1K-1 | 13 | 13 | 13 | 13 |

| Ka mana wela kikoʻī 20ºC, KJkg-1K-1 | 0.46 | 0.46 | 0.46 | 0.46 |

| Kiko heheʻeºC | 1500 | 1500 | 1500 | 1500 |

| Nā ʻano mīkini paha | ||||

| Ikaika tensile, N mm-2 | 680 | 680 | 680 | 650 |

| ʻO ka ikaika hua, N mm-2 | 470 | 475 | 475 | 450 |

| Paʻakikī, Hv | 230 | 230 | 230 | 230 |

| Ka uhaki ʻana i ka elongation,% | 20 | 18 | 18 | 18 |

| 900ºCTikaika tensile, N mm-2 | 40 | 34 | 37 | 34 |

| Ikaika kolo 800ºC | 11 | 6 | 8 | 6 |

| 1000ºC | 3.4 | 1 | 1.5 | 1 |

| Mākēneki | magnetic (I ka mahana 600ºC) | |||

| ʻO ka emissivity, nā kūlana oxidation | 0.7 | 0.7 | 0.7 | 0.7 |

Kikoʻī:

| ʻAno Alloy | Anawaena | Ke kū'ē ʻana | Uhi | Hoʻolōʻihi (%) | Kūlou | Max.Hoʻomau | Ke Ola Hana |

| (mm) | (μΩm)(20°C) | Ikaika | Nā Manawa | lawelawe | (nā hola) | ||

| (N/mm²) | Mahana (°C) | ||||||

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

Pōmaikaʻi:

ʻOi aku ka maikaʻi o ke kūpaʻa o ka hui nickelchromium me ke kūpaʻa kiʻekiʻe a paʻa, kū'ē i ka pala, a maikaʻi ke kūpaʻa ʻana i ka ʻoki ʻana i ka ʻili, ʻoi aku ka maikaʻi ma mua o ke kiʻekiʻe o ka mahana a me ka ikaika seismic, ductility maikaʻi, hana maikaʻi a me ka weldability.

E kākau i kāu leka ma aneʻi a hoʻouna mai iā mākou

Nā māhele huahana

-

Kelepona

-

Leka uila

-

Whatsapp

-

WeChat

ʻO Judy

150 0000 2421

-

Luna