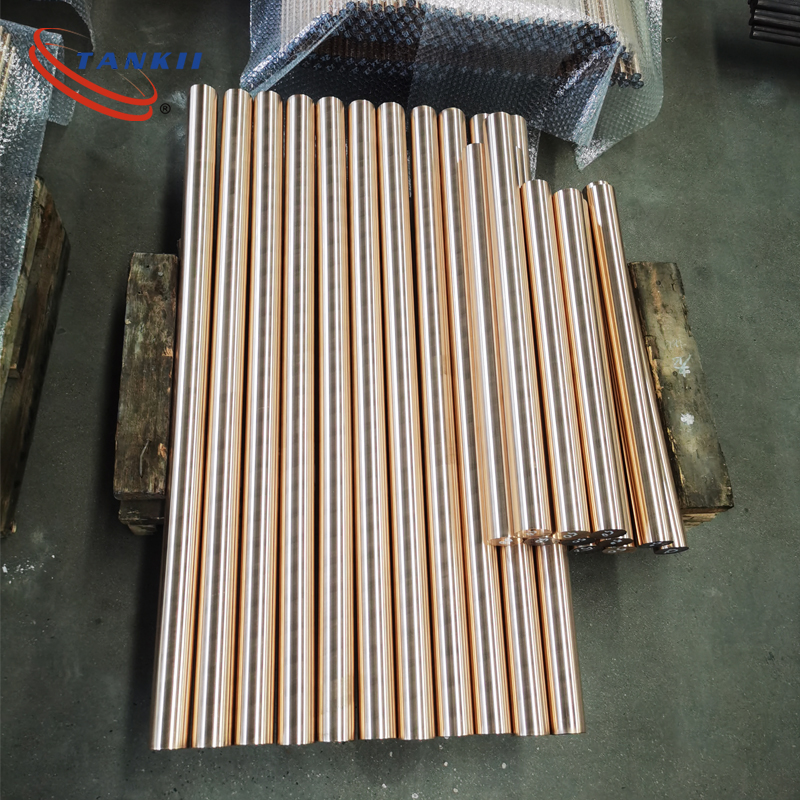

ʻO Inconel Alloy 625 718 600 Wire Uns N06625 Fine/ Filler/ Welding Wires

ʻO Inconel kahi ʻohana o nā super alloys austenitic nickel chromium.

ʻO nā mea hoʻohuihui Inconel he mau mea kū'ē i ka oxidation corrion i kūpono loa no ka lawelawe ʻana i nā wahi koʻikoʻi i kau ʻia i ke kaomi a me

wela. Ke hoʻomehana ʻia, hana ʻo Inconel i kahi papa oxide rich, paʻa, passivating e pale ana i ka ʻili mai ka hoʻouka hou ʻana. Mālama ʻo Inconel

ikaika ma luna o kahi ākea o ka mahana, kūpono no nā noi wela kiʻekiʻe kahi e hāʻule ai ka alumini a me ke kila i ka creep

ma muli o nā hakahaka kristal i hoʻoulu ʻia e ka thermally. Hoʻomohala ʻia ka ikaika wela kiʻekiʻe o Inconel e ka hopena paʻa

ka hoʻoikaika ʻana a i ʻole ka paʻakikī ʻana o ka ua, ma muli o ka metala.

ʻO Inconel 718 kahi hui nickel-chromium-molybdenum i hoʻolālā ʻia e kūʻē i nā ʻano kaiapuni ʻino loa, pitting a me ka crevice corrosion. Hōʻike pū kēia hui kila nickel i nā waiwai kiʻekiʻe loa, tensile, a me ka creep-rupture i nā mahana kiʻekiʻe. Hoʻohana ʻia kēia hui nickel mai nā mahana cryogenic a hiki i ka lawelawe lōʻihi ma 1200° F. ʻO kekahi o nā hiʻohiʻona ʻokoʻa o ka hui ʻana o Inconel 718 ʻo ia ka hoʻohui ʻana o ka niobium e ʻae i ka paʻakikī ʻana o ka makahiki e hiki ai ke annealing a me ka welding me ka ʻole o ka paʻakikī koke i ka wā hoʻomehana a me ka hoʻomaʻalili ʻana. Hana pū ka hoʻohui ʻana o ka niobium me ka molybdenum e hoʻopaʻakikī i ka matrix o ka hui a hāʻawi i ka ikaika kiʻekiʻe me ka ʻole o ka hoʻoikaika ʻana i ka wela. ʻO nā hui nickel-chromium kaulana ʻē aʻe i hoʻopaʻakikī ʻia ma o ka hoʻohui ʻana o ka alumini a me ka titanium. Hana maʻalahi ʻia kēia hui kila nickel a hiki ke hoʻopaʻa ʻia i loko o ke kūlana annealed a i ʻole precipitation (makahiki) paʻakikī. Hoʻohana ʻia kēia superalloy i nā ʻano ʻoihana like ʻole e like me ka aerospace, ka hana kemika, ka ʻenekinia moana, nā lako hana hoʻomalu haumia, a me nā reactors nuklea.

ʻO nā ʻāpana wela kiʻekiʻe, e like me nā lau turbine, nā vanes alakaʻi, nā disks turbine, nā disks compressor pressure kiʻekiʻe, ka hana mīkini a me nā keʻena kuni i hoʻohana ʻia i ka hana ʻana i nā turbines mokulele, nā moku a me nā ʻoihana kinoea ʻoihana.

| Mea | ʻInconel 600 | ʻInonel | ʻInonel 617 | ʻInonel | ʻInonel | ʻInonel | ʻInonel | |

| 601 | 690 | 718 | X750 | 825 | ||||

| C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

| Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

| Fe | 6~10 | hoʻomaha | ≤3 | hoʻomaha | 7~11 | hoʻomaha | 5~9 | ≥22 |

| P | ≤0.015 | ≤0.02 | ≤0.015 | – | – | – | – | – |

| S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

| Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

| Cu | ≤0.5 | ≤1 | – | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

| Ni | ≥7.2 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

| Co | – | – | 10~15 | ≤10 | – | ≤1 | ≤1 | – |

| Al | – | 1-1.7 | 0.8-1.5 | ≤0.8 | – | 0.2-0.8 | 0.4-1 | ≤0.2 |

| Ti | – | – | ≤0.6 | ≤1.15 | – | – | 2.25-2.75 | 0.6-1.2 |

| Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

| Nb+Ta | – | – | – | 4.75-5.5 | – | 4.75-5.5 | 0.7-1.2 | – |

| Mo | – | – | 8~10 | 2.8-3.3 | – | 2.8-3.3 | – | 2.5-3.5 |

| B | – | – | ≤0.006 | – | – | – | – | – |

Nā māhele huahana

-

Kelepona

-

Leka uila

-

Whatsapp

-

WeChat

ʻO Judy

150 0000 2421

-

Luna