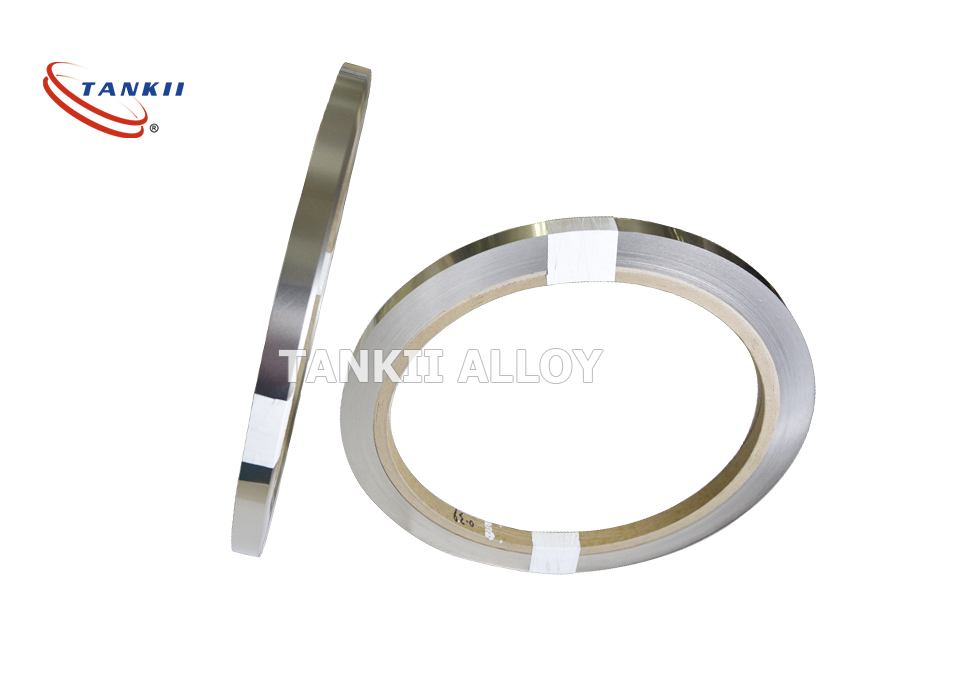

ʻO ka ʻōwili wehe o ka uea kū'ē FeCrAl mānoanoa 0.05mm

ʻO FeCrAl AlloyʻO ka Foil/Strip Coil 0.05mm ka mānoanoa no nā Metallic Honeycomb Substrates

ʻO ke kiʻekiʻe o ka alumini, i hui pū ʻia me ke kiʻekiʻe o ka chromium e hoʻonui ai i ka mahana scaling a hiki i 1425 C (2600F); Ma lalo o ke poʻo inoa o ke kūpaʻa wela, kēia mau meaʻO ke kola FeCrAlua hoʻohālikelike ʻia me nā mea hoʻohuihui kumu Fe a me Ni i hoʻohana pinepine ʻia. E like me ka mea i ʻike ʻia mai kēlā papa, ʻo kaʻO ke kola FeCrAlLoaʻa iā lākou nā waiwai maikaʻi loa i hoʻohālikelike ʻia me nā mea hoʻohui ʻē aʻe ma ka hapa nui o nā wahi.

Pono e hoʻomaopopo ʻia, i ka wā o nā kūlana mahana ʻokoʻa, ʻo ka hoʻohui ʻana o ka yttrium i ka hui AF i ʻike ʻia hoʻi ʻo nā hui Fecralloys, e hoʻomaikaʻi i ka hoʻopili ʻana o ka oxide pale, e hoʻolōʻihi ana i ke ola lawelawe o nā ʻāpana i loko o ka hui AF ma mua o ka papa A-1.

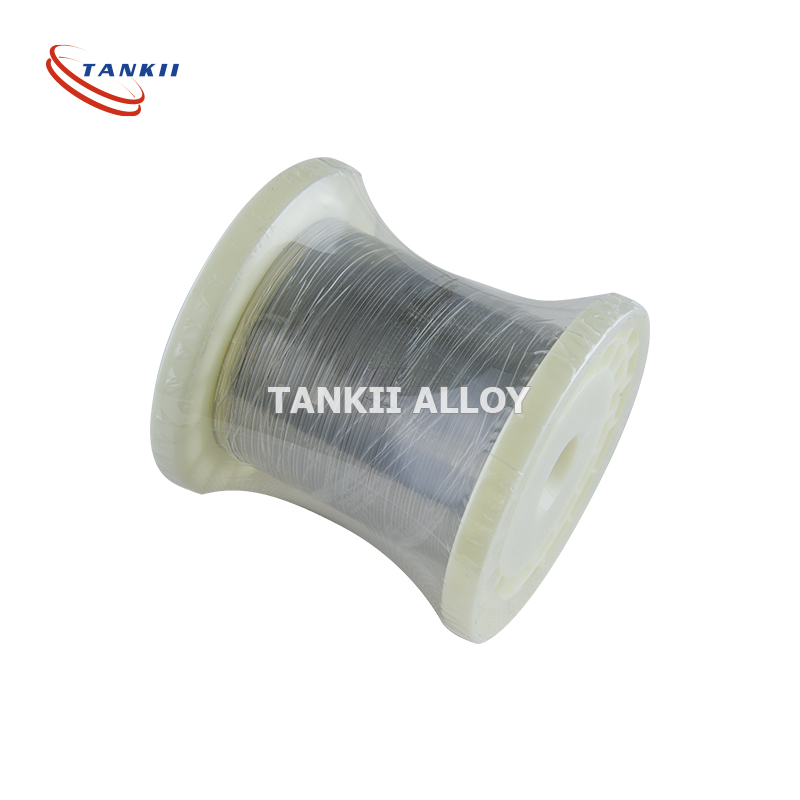

Hana ʻia nā uea hui Fe-Cr-Al i nā hui hao chromium alumini kumu e loaʻa ana nā mea liʻiliʻi o nā mea reactive e like me yttrium a me zirconium a hana ʻia e ka hoʻoheheʻe ʻana, ka ʻōwili kila, ka forging, annealing, ka huki ʻana, ka mālama ʻana i ka ʻili, ka hoʻāʻo hoʻomalu kū'ē, a me nā mea ʻē aʻe.

Ua hoʻohālikelike ʻia ke uea Fe-Cr-Al e kahi mīkini hoʻoluʻu wikiwiki kiʻekiʻe kahi e hoʻokele ʻia ai ka mana o ka mana e ke kamepiula, loaʻa lākou ma ke ʻano he uea a me ka lipine (ʻāpana).

Nā hiʻohiʻona a me nā pono

1. Kiʻekiʻe ka mahana hoʻohana, hiki i ka mahana hoʻohana kiʻekiʻe loa ke hiki i 1400C (0Cr21A16Nb, 0Cr27A17Mo2, a pēlā aku)

2. Ka helu kū'ē o ka mahana haʻahaʻa

3. ʻOi aku ka haʻahaʻa o ke koina hoʻonui wela ma mua o nā super-alloys Ni-base.

4. Ke kū'ē uila kiʻekiʻe

5. Kū'ē maika'i i ka palaho ma lalo o ke ana wela ki'eki'e, ma lalo o ka lewa e loa'a ana nā sulfides

6. Ukana ʻili kiʻekiʻe

7. Kūpaʻa kolo

8. ʻO ke kumukūʻai haʻahaʻa o nā mea maka, ka nui haʻahaʻa a me ke kumukūʻai haʻahaʻa ke hoʻohālikelike ʻia me ka uea Nichrome.

9. ʻOi aku ka maikaʻi o ke kūpaʻa ʻana i ka oxidation ma 800-1300ºC

10. Ola lawelawe lōʻihi

ʻO ke kūkulu ʻia ʻana o nā pae alumina metastable ma muli o ka oxidation o nā mea kalepaʻO ke kola FeCrAlua nānā ʻia nā uea (0.5 mm ka mānoanoa) ma nā mahana like ʻole a me nā wā. Ua hoʻomake ʻia nā laʻana i ka lewa me ka hoʻohana ʻana i kahi mea kālailai thermogravimetric (TGA). Ua kālailai ʻia ke ʻano o nā laʻana i hoʻomake ʻia me ka hoʻohana ʻana i kahi Electronic Scanning Electron Microscope (ESEM) a ua hana ʻia ka nānā ʻana o X-ray ma ka ʻili me ka hoʻohana ʻana i kahi mea kālailai Energy Dispersive X-Ray (EDX). Ua hoʻohana ʻia ke ʻano o X-Ray Diffraction (XRD) e wehewehe i ke ʻano o ka ulu ʻana o ka oxide. Ua hōʻike ka haʻawina holoʻokoʻa he hiki ke ulu i ka gamma alumina wahi kiʻekiʻe ma kaʻO ke kola FeCrAlnā ʻili uea i ka wā i oxidized isothermally ma luna o 800°C no kekahi mau hola.

| Hao Chrome Aluminum | |||||||

| ʻOCr25Al5 | ʻO CrAl25-5 | 23.0 | 71.0 | 6.0 | |||

| ʻOCr20Al5 | ʻO CrAl20-5 | 20.0 | 75.0 | 5.0 | |||

| ʻOCr27Al7Mo2 | 27.0 | 65.0 | 0.5 | 7.0 | 0.5 | ||

| ʻOCr21Al6Nb | 21.0 | 72.0 | 0.5 | 6.0 | 0.5 | ||

| Hao Chrome Aluminum | ||

| ʻOCr25Al5 | Hiki ke hoʻohana ʻia i nā kūlana hana a hiki i 1350°C, ʻoiai hiki ke lilo i mea e palupalu ai. | Nā mea hoʻomehana o nā umu wela kiʻekiʻe a me nā mea hoʻomehana radiant. |

| ʻOCr20Al5 | He mea hoʻohuihui ferromagnetic hiki ke hoʻohana ʻia i nā mahana a hiki i 1300°C. Pono e hoʻohana ʻia ma nā wahi maloʻo e pale aku ai i ka pala. Hiki ke lilo i mea palupalu i nā mahana kiʻekiʻe. | Nā mea hoʻomehana o nā umu wela kiʻekiʻe a me nā mea hoʻomehana radiant. |

Nā māhele huahana

-

Kelepona

-

Leka uila

-

Whatsapp

-

WeChat

ʻO Judy

150 0000 2421

-

Luna