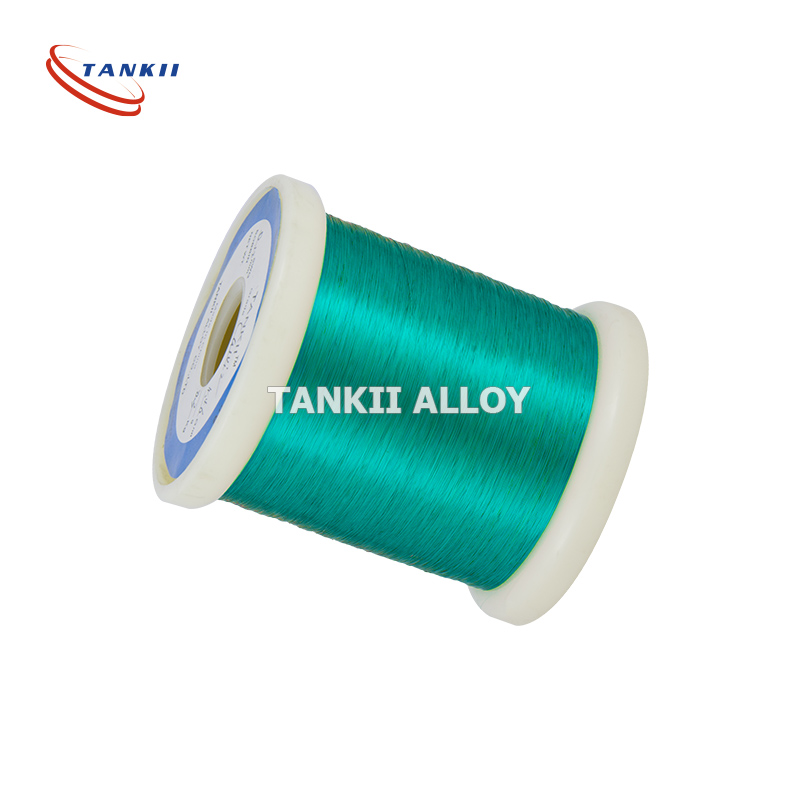

0.2mm 130 Papa Enameled Uea waihoʻoluʻu Poʻe Copper Alloy Manganin

130 Papa waihoʻoluʻu poepoe keleawe huila Manganin Enameled Uea

1. Mea Ho'ākāka Nui

Copper nickel alloy, he haʻahaʻa ka uila resisitance, maikaʻi ka wela a me ka corrosion-kūʻē, maʻalahi ke hana a me ke alakaʻi welded.Hoʻohana ʻia ia e hana i nā ʻāpana koʻikoʻi o ka relay overload thermal, haʻahaʻa haʻahaʻa haʻahaʻa thermal circuit breaker, a me nā mea uila.He mea koʻikoʻi nō hoʻi ia no ke kaula hoʻomehana uila.Ua like ia me s type cupronickel. ʻO ka nui o ka haku mele ʻana o Nickel, ʻoi aku ka nui o ke kālā keʻokeʻo o ka ʻili.

3.Chemical Composition a me ka waiwai nui o Cu-Ni Low Resistance Alloy

| Papa Waiwai | CuNi1 | CuNi2 | CuNi6 | CuNi8 | CuMn3 | CuNi10 | |

| Hui Kemika Nui | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | ʻO Bal | ʻO Bal | ʻO Bal | ʻO Bal | ʻO Bal | ʻO Bal | |

| ʻO ka wela o ka lawelawe mau loa (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Hiki ke pale i ka 20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Māmā (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| ʻO ka hoʻoili wela (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Ikaika U'i (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Kakahi hehee (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Hoʻolālā Micrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Waiwai Magnetic | ʻaʻole | ʻaʻole | ʻaʻole | ʻaʻole | ʻaʻole | ʻaʻole | |

| Papa Waiwai | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNi44 | |

| Hui Kemika Nui | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | ʻO Bal | ʻO Bal | ʻO Bal | ʻO Bal | ʻO Bal | ʻO Bal | |

| ʻO ka wela o ka lawelawe mau loa (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Hiki ke pale i ka 20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Māmā (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| ʻO ka hoʻoili wela (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Ikaika U'i (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Kakahi hehee (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Hoʻolālā Micrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Waiwai Magnetic | ʻaʻole | ʻaʻole | ʻaʻole | ʻaʻole | ʻaʻole | ʻaʻole | |

2. Enamelled Wire Introduction a me nā noi

ʻOiai i wehewehe ʻia he "enameled", ʻaʻole i uhi ʻia ka uea enameled me kahi papa o ka pena enamel a i ʻole me ka enamel vitreous i hana ʻia me ka pauka aniani.Hoʻohana maʻamau ka uea magnet hou i hoʻokahi a i ʻehā mau papa (ma ke ʻano o ka uea ʻano quad-film) o ka polymer film insulation, pinepine o ʻelua mau haku mele, e hāʻawi i kahi papa insulating paʻakikī.Hoʻohana ʻia nā kiʻiʻoniʻoni hoʻokaʻawale uea Magnet (no ka hoʻonui ʻana i ka pae wela) polyvinyl formal (Formar), polyurethane, polyimide, polyamide, polyster,poliester-polyimide, polyamide-polyimide (a i ʻole amide-imide), a me ka polyimide.Hiki ke hana i ka uwea magnet insulated polyimide a hiki i 250 °C.Hoʻonui pinepine ʻia ka insulation o ka uea mānoanoa mānoanoa a i ʻole rectangular ma ke kāʻei ʻana iā ia me kahi polyimide kiʻekiʻe a i ʻole fiberglass tape, a hoʻopau pinepine ʻia nā windings i hoʻopiha ʻia me kahi varnish insulating e hoʻomaikaʻi i ka ikaika insulation a me ka hilinaʻi lōʻihi o ka wili.

Hoʻopili ʻia nā ʻōwili kākoʻo ponoʻī me ka uwea i uhi ʻia me ʻelua mau papa, ʻo ka ʻaoʻao loa he thermoplastic e hoʻopaʻa i nā huli i ka wā i wela ai.

ʻO nā ʻano insulation ʻē aʻe e like me ka fiberglass yarn me ka varnish, ka pepa aramid, ka pepa kraft, ka mica, a me ka kiʻiʻoniʻoni polyester e hoʻohana nui ʻia a puni ka honua no nā noi like ʻole e like me nā transformers a me nā reactors.Ma ka ʻāpana leo, hiki ke loaʻa kahi uea i hana ʻia i ke kālā, a me nā insulators ʻē aʻe, e like me ka pulupulu (i kekahi manawa i hoʻopaʻa ʻia me kekahi ʻano coagulating agent/thickener, e like me ka beeswax) a me polytetrafluoroethylene (PTFE) hiki ke loaʻa.He pulupulu, pepa, a siliki paha na mea insulation kahiko, aka, he mea pono wale no keia no na mea wela haahaa (a hiki i 105°C).

No ka maʻalahi o ka hana ʻana, aia kekahi uea magnet haʻahaʻa haʻahaʻa haʻahaʻa i hiki ke wehe ʻia e ka wela o ka soldering.'O ia ho'i, hiki ke hana 'ia nā pili uila ma nā wēlau me ka wehe 'ole 'ana i ka insulation ma mua.